Dynamic Microphones | Condenser Microphones | Phantom Power | Other Types of Microphones

Like phono cartridges, headphones and loudspeakers, the microphone is a transducer – in other words, an energy converter. It senses acoustic energy (sound) and translates it into equivalent electrical energy. Amplified and sent to a loudspeaker or headphone, the sound picked up by the microphone transducer should emerge from the speaker transducer with no significant changes.

How a Microphone Works

While there are many ways to convert sound into electrical energy, we’ll concentrate on the two most popular methods: dynamic and condenser. These are the types of microphones most often found in recording studios, broadcast, motion picture video production, and on stages for live sound reinforcement.

Why Microphone Selection is Important

The microphone is, by its nature, at the very beginning of most sound systems and recording applications. If the mic can’t capture the sound clearly and accurately, and with low noise, even the best electronics and speakers following it won’t produce the optimum sound. So it’s important to invest in good microphones, to maximize sound system performance potential.

Dynamic Microphones

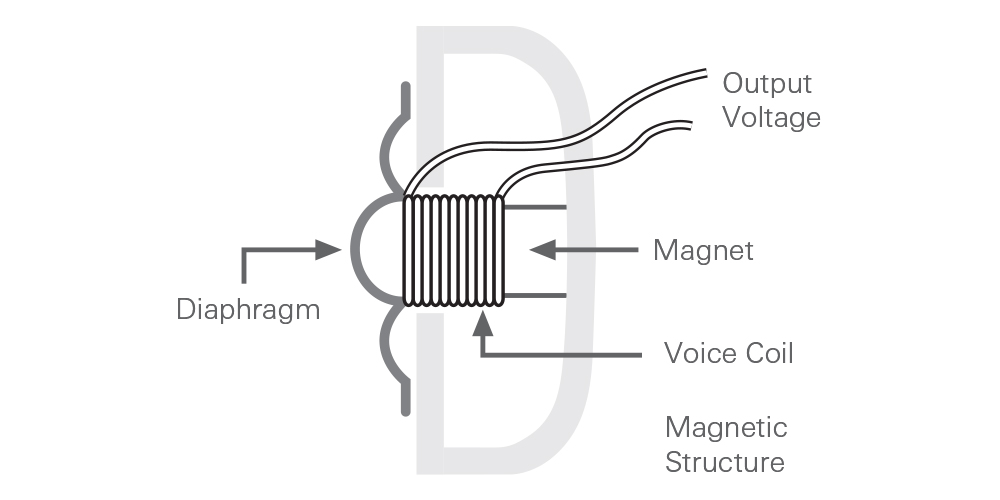

Comparing microphones to loudspeakers may help you to understand their operation. Dynamic microphones are similar to conventional loudspeakers in many respects. Both have a diaphragm (or cone) with a voice coil (a long coil of wire) attached near the apex. Both have a magnetic system with the coil in its gap. The difference is in how they are used.

With a speaker, current from the amplifier flows through the coil. The magnetic field created by current flowing through the voice coil interacts with the magnetic field of the speaker’s magnet, forcing the coil and attached cone to move back and forth, producing sound output.

Figure 1: Dynamic Microphone Element

A dynamic microphone operates like a speaker in reverse. The diaphragm is moved by changing sound pressure. This moves the coil, which causes current to flow as lines of flux from the magnet are cut. So, instead of putting electrical energy into the coil (as in a speaker) you get energy out of it. In fact, many intercom systems use small speakers with lightweight cones as both a speaker and a microphone, by simply switching the same transducer from one end of the amplifier to the other! A speaker doesn’t make a great microphone, but it’s good enough for that application.

Dynamic microphones are renowned for their ruggedness and reliability. They need no batteries or external power supplies. They are capable of smooth, extended response, or are available with “tailored” response for special applications. Output level is high enough to work directly into most microphone inputs with an excellent signal-to-noise ratio. They need little or no regular maintenance, and with reasonable care will maintain their performance for many years.

Condenser Microphones

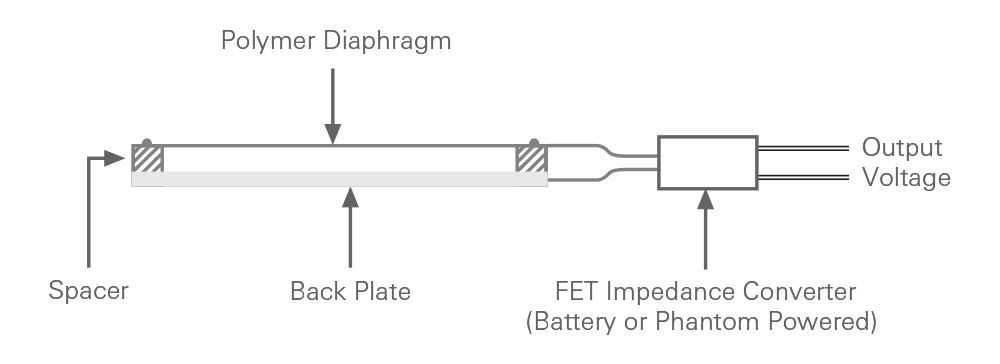

Condenser (or capacitor) microphones use a lightweight membrane and a fixed plate that act as opposite sides of a capacitor. Sound pressure against this thin polymer film causes it to move. This movement changes the capacitance of the circuit, creating a changing electrical output. (In many respects a condenser microphone functions in the same manner as an electrostatic tweeter, although on a much smaller scale and “in reverse.”)

Condenser microphones are preferred for their very uniform frequency response, and ability to respond with clarity to transient sounds. The low mass of the diaphragm permits extended high-frequency response, while the nature of the design also ensures outstanding low-frequency pickup. The resulting sound is natural, clean and clear, with excellent transparency and detail.

Two basic types of condenser microphones are currently available. One uses an external power supply to provide the polarizing voltage needed for the capacitive circuit. These externally-polarized microphones are intended primarily for professional studio use or other extremely critical applications.

A more recent development is the electret condenser microphone (Fig. 2). In these models, the polarizing voltage is impressed on either the diaphragm or the back plate during the manufacturing process, and this charge remains for the life of the microphone.

Figure 2: Electret Condenser Element

The best electret condenser microphones are capable of very high-quality performance, and are used extensively in broadcast, recording and sound reinforcement.

Due in part to their low-mass diaphragms, condenser microphones are inherently lower in handling or mechanical noise than dynamic microphones. For all of its electret condenser designs, Audio-Technica has elected to apply the polarizing voltage, or fixed-charge, to the back plate rather than the diaphragm. By doing this, a thinner material may be used for the diaphragm, providing a considerable performance advantage over electret microphones of conventional design. Many Audio-Technica microphone diaphragms, for example, are only 2 microns thick (less than 1/10,000th of an inch)!

Condenser microphones have two other design advantages that make them the ideal (or the only) choice for many applications: they weigh much less than dynamic elements, and they can be much smaller. These characteristics make them the logical choice for line – or “shotgun” – microphones, lavaliers and miniature microphones of all types.

Attempts at miniaturizing dynamic microphones result in greatly reduced low frequency response, overall loss in acoustic sensitivity, and higher mechanical or handling noise.

Phantom Power

While the electret condenser microphone doesn’t need a power supply to provide polarizing voltage, an FET impedance matching circuit inside the microphone does require some power. This may be supplied by a small low-voltage internal battery or by an external “phantom” supply.

Phantom powering is a technique which delivers a DC voltage to the microphone through the same shielded two-conductor cable that carries the audio from the mic. The phantom power may be supplied either by the mic mixer or from an external supply that is inserted into the line between the microphone and mixer input. For phantom power to function, the line between the power supply and the microphone must be balanced to ground, and uninterrupted by such devices as filters or transformers which might pass the audio signal but block DC. Phantom power also requires a continuous ground connection (Pin 1 in the XLR-type connector) from the power supply to the microphone. The supply delivers positive DC voltage equally to both signal conducting leads, and uses the shield as a return path, or negative. Balanced output dynamic microphones are not affected by the presence of phantom power, since there is no connection between the shield and either signal lead and, therefore, no circuit for the DC voltage. While the application of phantom power is prohibited for most ribbon microphones, Audio-Technica’s ribbon microphones require phantom power for operation.

Phantom power supplies are available in various output voltages ranging from as low as 9 volts up to 48 volts. They may be designed to operate from AC line voltages or from internal batteries.

Externally polarized or discrete condenser microphones seldom have internal battery power. Instead, a phantom power source is used to provide both the polarizing voltage for the element and to power the impedance converter. This type is sometimes called a pure condenser.

Other Types of Microphones

There a number of ways to translate sound into electrical energy. Carbon granules are used as elements in telephones and communications microphones. And some low-cost microphones use crystal or ceramic elements that are generally OK for speech, but are not seriously considered for music or critical sound reproduction.

Ribbon Microphones

The ribbon offers the purest form of transduction: a thin strip of aluminum moves between two magnets, inducing voltage. Prized for their distinctive warm sound, ribbon mics traditionally were quite fragile; there were also widespread problems with compatibility.

To increase the durability of the ribbon microphone Audio-Technica developed a patent-pending forming process that protects the dual ribbons from lateral flexing and distortion; there is no need to store the mics vertically as is recommended for many ribbon microphones. For increased sensitivity, the Audio-Technica ribbon cartridge features a dual-ribbon design: the two ribbons are suspended between the top and bottom edges of extremely powerful N50 neodymium magnets.

A longstanding problem with old-school ribbons is that they could be harmed by exposure to phantom power. Audio-Technica ribbon microphones actually require 48V phantom power for operation. We use the phantom power—not for each microphone’s dynamic ribbon transducer—but for its active electronics, which bring its output to near condenser microphone level. This higher output and stable impedance offer maximum compatibility with microphone preamplifiers.

Increasingly popular for broadcast, studio and live applications, ribbon microphones are often designed to respond to sound from both the front and back, and are sometimes used when a bidirectional pickup pattern is required - which brings us to the next major microphone classification.